Hello all,

I have 5 workcells in my classroom and all my students are having issues. These issues have been apparent for a while but are really making Lab 7 quite difficult. I am worried that if it isn’t fixed later labs will be impossible to accomplish.

The issues I am having are:

-

The workcell can not repeat coordinates. In the same run, same code all 5 workcells will not return to the same coordinate repeatedly. Every time the students hit the white box the robotic arm will move to a new physical location despite saying it is the same coordinate. This is not a potentiometer or motor issue as this happens on all 5 workcells.

-

The arms move much slower than in the example videos in the VEX V5 Workcell Educator Certification Course. They are using the same code and all 5 workcells move much slower.

-

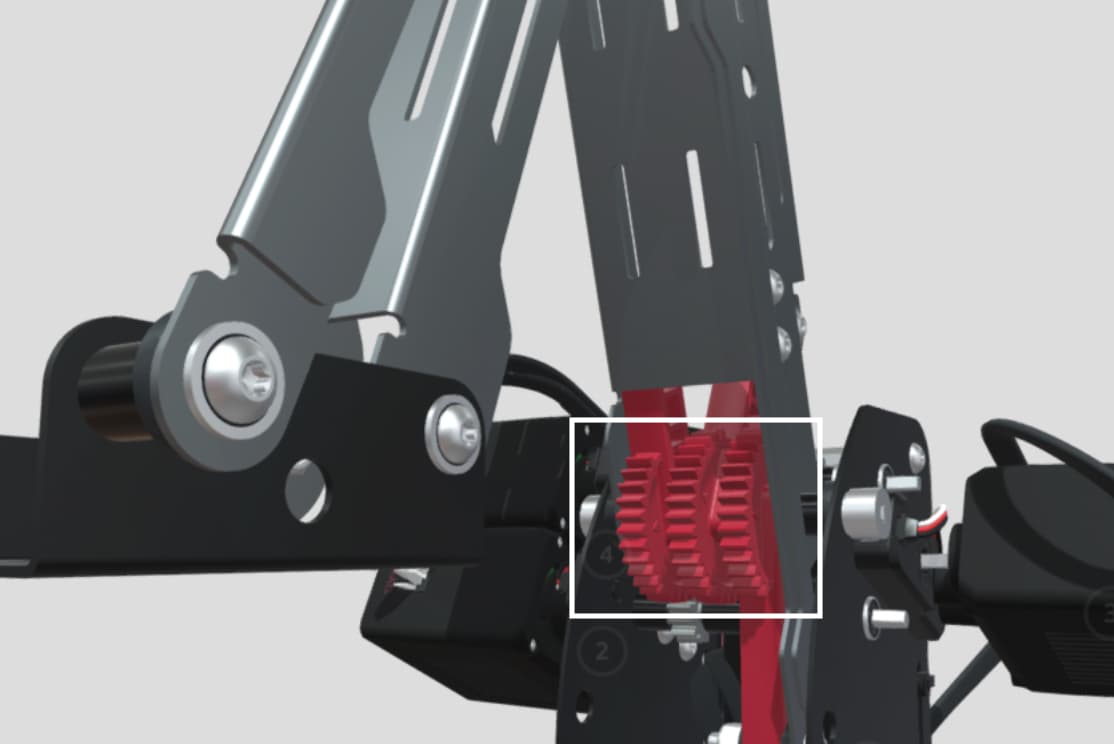

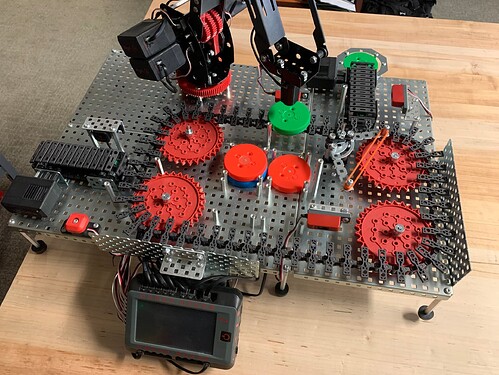

Some of the robots shake as they move, I am having students look the joints to ensure no bolts are overtightened but after the shake still remains. But also there is a LOT of play in the gears. They can move at least 1/8 inch without engaging the gears/ potentiometer. I don’t know why this is, or how it is possible to have accurate movements with this amount of play.

I am hoping I can get some help here, as VEX support is taking too long to respond and has not been helpful. As an educator who is trying to start a robotics program and show the district their money was well spent, this has been a frustrating experience. Thank you for any tips and tricks, advice, or moral support!

1 Like

Hi @Matthew_Kearns, I’m sorry to hear you are experiencing issues with the V5 Workcell. To help you more effectively and efficiently, could you please share some images or videos showing the issues with the Workcells? Seeing what’s happening firsthand will allow us to provide more accurate advice and solutions.

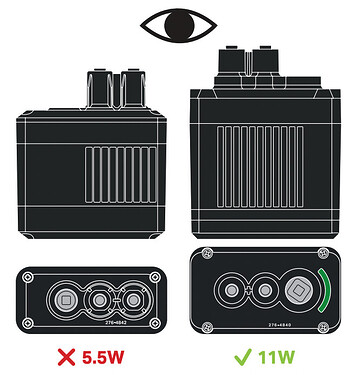

Given your feedback, I do have an initial question that might help us get to the bottom of this. Could you let us know which motors are currently installed on the arms of your Workcells? Are they the 11W (larger) motors or the 5.5W (smaller) motors? You can refer to the attached image to identify them. The reason I’m asking is that the use of the smaller, 5.5W motors might explain some of the issues you’re experiencing, such as the shaking, slower movement, and inaccuracies.

In the meantime, check out

Frequently Asked Questions of the V5 Workcell from the VEX Library as it may answer some additional questions you may have. Thanks, and I look forward to correcting these issues with you!

1 Like

Hey Matthew!

They are using the 11W motors. I will attach a video of one of the robots in action.

Hi @Matthew_Kearns  thank you for posting this video, it’s really helpful to start to try to understand what the problem could be.

thank you for posting this video, it’s really helpful to start to try to understand what the problem could be.

Can I also ask you to provide the code file or an image of it so I can see what that looks like as well?

Thanks for your patience as we figure out this issue together.

Yes, I will have them send me the code tomorrow. They are following the lab so it should be pretty similar to what Lab 7 for the workcell has them do.

Perfect, thank you!

In the meantime, @Matthew_Goodwin might have some more ideas.

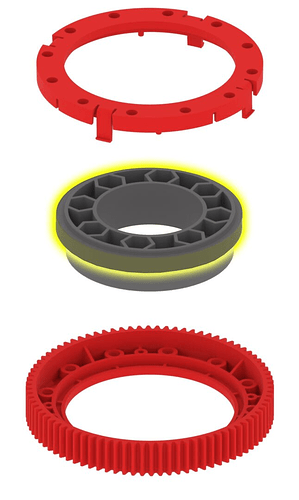

I’m also wondering if lubricating the turntable would help at all. Information on that could be found here.

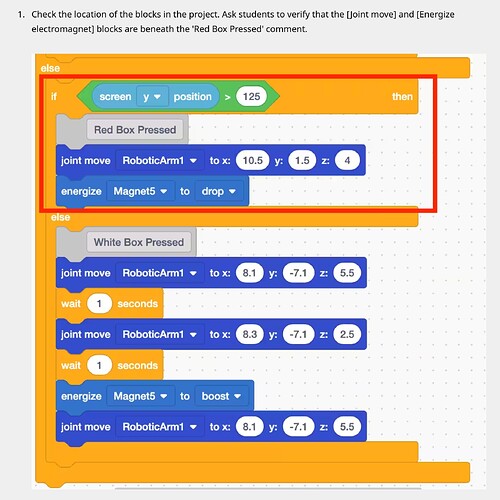

Another thing to think about is linear vs. joint move with those red gears, which is why I wanted to look at the code, just to see

The three red Claw Gear Cranks will remain stationary during Joint move, and will become active during Linear move. I can see them moving slightly in your video, so linear move might be enabled here. But it’s good just to check all options!

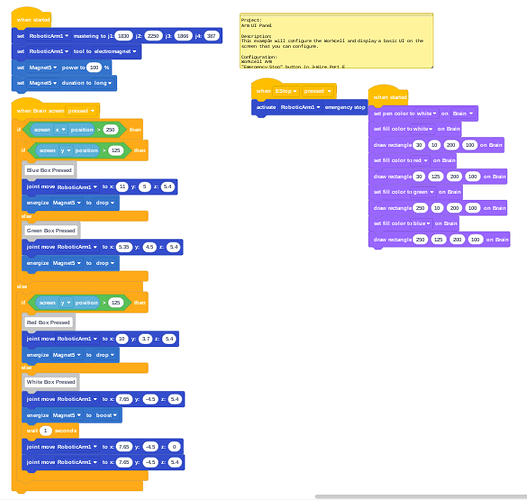

Here is a screenshot of the code running in the video.

Hi @Matthew_Kearns! Thank you so much for providing an image of the code, this is really helpful. For the ‘White box pressed’ section of the code, I would recommend adding in another [Wait 1 second] in addition to moving the magnet block down, I think that could help slightly.

Also switching the blocks from Joint move to Linear could make it slightly more precise.

My other question is how often do the students update the mastering values? Do they do it at the beginning of each class before they run the Workcell? I’ve found in my experience that updating the mastering values often is important, so I often check that when troubleshooting

2 Likes

I can add the wait 1 second and switch from joint to linear and see if that helps. The lab, however, shows the code with joint move and the arm moves much faster and smoother than all of my stations.

Also, hitting the white box more than once (to repeat with a different color) causes the arm to continue creeping forward. I will have my students change the code but I don’t think it will fix the issue all the robots seem to be having.

At first I thought the mastering values would stay consistent for longer than a day but now my students also check the values to start the day and update their code with the new values. Once I’ve tested these I will report back!

Sounds good.

I’m also wondering, do you keep the Batteries connected to wall power while you’re running the programs, or are they just running on Battery power alone? I am wondering if they are moving a little slower because of low Battery power.

Also, I apologize if some of these troubleshooting steps you’ve already contemplated, I’m just going through the list of items that I always check when this happens

No worries, I know how troubleshooting is. You have to go through the steps to eliminate all possible issues.

Some students keep them plugged into the wall but I have/do check to make sure battery power isn’t an issue. They charge their batteries at the end of the period for the next day.

@Matthew_Kearns I noticed something interesting towards the end of the video you shared—the current draw on your V5 Brain seemed a tad higher than what’s typically expected. This may be because of an unlubricated turn table, which Lauren shared how to rectify this above. To delve deeper into this demonstration, could you please capture and share another video that clearly displays this current draw value; as well as the motor dashboard for Joint 1? These readings can provide insightful data, as higher current draw could mean that the motor is exerting extra effort, potentially leading to some of the issues you’re encountering.

For comparative purposes, I’ve included a video of my own arm in operation. In the second half of the video, I demonstrate what the values on the V5 Brain might look like if the arm encounters resistance. (Please take note: do not attempt to recreate this scenario with your arm, as it’s strictly for demonstration purposes and could result in harm to the equipment  )

)

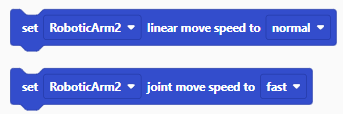

Secondarily you can increase the speed of the linear and joint movement commands through the usage of the blocks shown below. If you increase the movement speed higher, I highly recommend what Lauren mentioned as well by including [Wait] blocks between movements to allow for the arm to fully achieve the accurate coordinate before shortcutting it and moving on.

I think this is because the electromagnet was on during that part of the video.

I was having a hard time doing this since it was a short code, I am going to run a different code and try to get you the video. I did see the motor for joint 1 hit one watt which is not very high. I will do another test but I don’t think the joint is using excessive power from my quick test.

1 Like

Here is a video that shows you the information you wanted and shows you my biggest issue which is repetitive motions.

You can see how the arm drifts, this is worse on lab 7 where the students press the white box to pick up another disc.

Also, I created my own code using linear movement and fast speed and it stacked 5 in a row. I am going to share my findings with my students tomorrow to see if I can get these results repeated with them.

*UPDATE I just did it on another robot and it is creeping forward on the x axis each time.

@Matthew_Kearns

Thank you for sharing the additional videos and conducting further tests on your end. From your latest video, I observed the arm drift you mentioned, and this is indeed a recognized challenge with the V5 Workcell, especially when executing repetitive precise motions. The issue seems to stem from the mechanical play in the gears and the precision of the motors and potentiometers, which can result in slight inaccuracies accumulating over consecutive movements.

It’s great to hear that your own code with linear movement and increased speed managed to stack five discs in a row consistently on one robot. However, the creeping forward on the x-axis on another robot indicates that these inaccuracies can vary between individual Workcells.

Here are a few recommendations and considerations to mitigate these issues:

- Calibration and Mastering: Ensure that all robots are properly calibrated and mastered at the start of each session. Even slight discrepancies in the mastering values can result in noticeable errors during operation.

- Regular Maintenance: Make sure all mechanical components are in good condition, and apply lubrication to the turntable as suggested earlier. This can help reduce friction and ensure smoother movements.

- Share Learnings: Your findings with the custom code and different movement settings are valuable. Sharing these insights with your students can help them better understand the capabilities and limitations of the system, turning this challenge into a learning opportunity.

- Experiment and iterate!

Attached is an experiment I was playing around with to increase the efficiency of my Workcell. Knowing my arm may fail at some points due to technical inaccuracy, I can account for that and take measures to try and mitigate those shortcomings.

Lastly I’ll leave you with some tips to ensure the coordinates you obtain are as accurate as possible. When manually moving the arm, ensure you do not measure a point when the arm is stretching it’s mechanical play in the gears. For instance, see the video below. I can move my arm a great deal, but the coordinates are not changing.

To obtain more accurate coordinates, use movements from the first major axes, the base (shown below). Limiting the number of failure points when obtaining these values can make your Workcell more accurate accounting for the mechanical play in the gears.

The play was what I, and my students, were thinking might be causing some of our issues as well. Thank you for your and @Lauren_Harter 's help. I will keep tinkering.

2 Likes

Sounds good @Matthew_Kearns! Please keep @Matthew_Goodwin and I updated if we can help further

Hey @Lauren_Harter and @Matthew_Goodwin, I was wondering if you could help me figure out what is causing one of my workcells to creep forward with repeated actions. Could this be an issue with the potentiometer?

Hi @Matthew_Kearns! Are all of your joints passing?

In my experience, when there is a problem with the potentiometer it rotates endlessly, never stopping in range during the mastering process.

Is this something you’re experiencing? If not, then I’m thinking it is probably not the potentiometer.

However, @Matthew_Goodwin can probably speak a little more on looking at the values from the potentiometer from the devices screen.

![]()