I am new to Workcell, so my students and I are figuring it out together. They got to the part in the build instructions where it says to run the arm install project (steps 36-42). The joints are all failing, and we tried to use the Target function (the full arm is not attached yet, so I don’t think this would damage any equipment since the motors are mostly free spinning). We got one joint passing, but it is spinning so much that the rubber band is stretched really far, so we stopped.

I have read over the mastering page and have seen the page with instructions on how to fix the joints if mastering fails. This all seems to be done after the build is completed. The build instructions in steps 36-42 is not very clear on if you have to get the joints to passing at this point, or if we should move on and worry about it later.

Should we fix the joint values now or after the arm is completely built? Are there instructions on how to fix the values during the build? What about the rubber band?

Any advice on this mid-build arm install would be greatly appreciated.

Hi @Esti_Stith! Sorry to hear about the trouble getting the joints to master.

Yes, I would get them to pass before continuing on with the build, otherwise you will have to take the arm apart.

Here are two video resources that I think are good if you’d like to check them out:

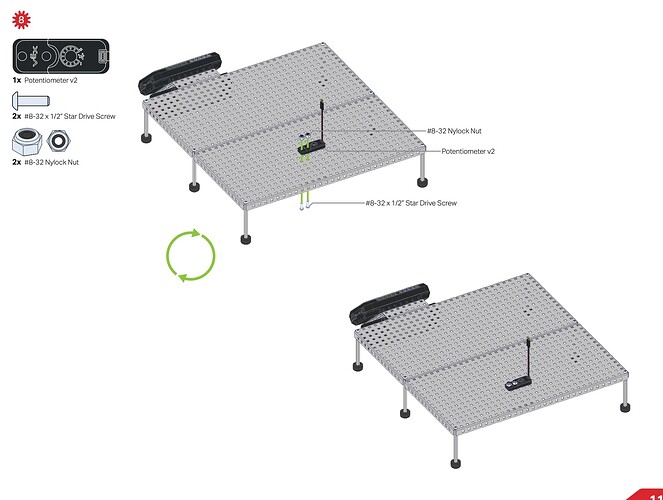

I would also make sure the potentiometer is assembled correctly from step 8.

I would do step 8 of this article if your Workcell arm is spinning about the base, that means Joint 1 is out of master and is trying to get into master.

If all of this still doesn’t work, if you’d like to upload a video here of what is happening, I can help diagnose the problem further.

Thanks

Thank you!

We have been trying this, but we cannot get the joint 1 arm in the correct range. One group, the values jump from 0, to 149, to 204, to 249, back to 0. It keeps cycling through the same numbers and never goes any higher than that.

The other group, the values go through the whole range but it still jumps around a lot. We can’t get it to center within the passing range. We will get it to the passing range, and then it will jump up and down by 200-300 and it never stays within passing. No idea how to move forward.

The other joints seem to be behaving (though we haven’t officially tried to get them within range)

I’m sorry to hear this is happening @Esti_Stith, would you be able to send me a video here so I can see what is going on?

Have you tried swapping the potentiometer with a different one just to see if it is a faulty potentiometer?

I would also make sure all the 3-wire cables are connected fully to each other (if using an extender) or into the Brain (I see this issue a lot  )

)

I talked about this a little in this other thread.

We can also schedule a 1-1 Session to walk through this together if that would be more helpful.

Here is a video: https://www.youtube.com/shorts/RuJnMP2I_DY

In this video I am turning the shaft VERY slowly.

All wires are definitely connected correctly.

We are changing potentiometers now. I hope this is not the issue because that means that 3 of our brand new potentiometers are faulty on first use.

Well, the good news it that replacing the potentiometers seemed to fix the issue with joint 1. The bad news is that it seems that (so far) at least 3/16 of our new potentiometers aren’t working.

Thanks!

Hi Esti,

I’d recommend connecting with support@vex.com via email to see about getting replacements for those potentiometers. There is also a phone number you can contact for support with product/software as well- Phone: (833) 297-6268, Monday - Friday, 7am - 5pm CST.